The full name of 5S management is 5S on-site management method, which originated in Japan and refers to the effective management of production factors such as personnel, machines, materials, and methods in the production site. In order to effectively improve the management level of the production site, Comprex has always regarded 5S management as an important management project and implemented it.

01.Taking multiple measures into a system

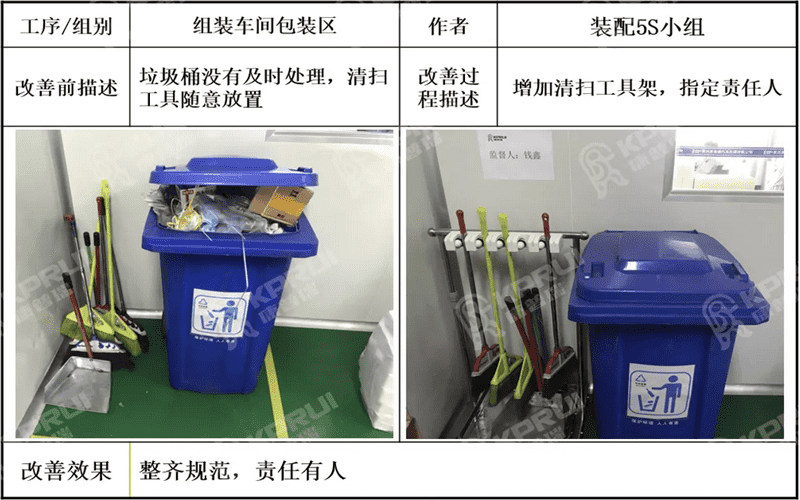

KPRUI adopted multiple measures such as the establishment of a 5S promotion team, the establishment of standard operating procedures, setting a benchmark for monthly appraisal, and the inclusion of a rationalization improvement platform to guide employees to actively participate, and formed a set of 5S management system.

The company established a 5S promotion team led by the General Manager’s Office and formulated the《5S Management Measures》 with clear job responsibilities, regular inspections, mutual inspections, and random inspections, and weekly summary of last week’s on-site inspection data and key improvement projects.

For equipment, quality inspection, warehouses, machining, assembly, office and administrative buildings, etc., establish the “5S operation instructions” for their respective regions, and update them regularly according to the actual situation on the site. Each department regularly monitors and confirms the site every day.

In order to focus on typical leadership and establish benchmarking, at the beginning of each month, we summarize the improvement data of each 5S executive team of the previous month, and conduct evaluations, reward the good and punish the bad, create a positive atmosphere, and use the power of example to influence everyone.

02. Perseverance shows results

Through long-term unremitting efforts, 5S management has enabled KPRUI to achieve visualization, customization, site cleanliness and standardization, achieving a five-star management site, improving the on-site operating environment, ensuring operating order, and ensuring safe production.

03. Continuous improvement becomes a culture

5S management is an important means to achieve lean production. In order to allow employees to fully understand the meaning of 5S management and make it a corporate culture gene flowing in the blood of every KPRUI employee, KPRUI will continue to improve in the following aspects :

1.Correctly understanding of 5S. Let employees fully identify value-added activities and wasteful behaviors on site, and strengthen publicity through such as 5S special issues, so that employees can correctly understand 5S, and put an end to the idea of “I am too busy at work to do 5S”.

2. Benchmarking energy. Establishing a 5S model area and maintain 5S, which is constantly iterating the benchmark area, making it a long-term leading benchmark for KPRUI, with points and faces, and playing a role as a benchmark.

3, Attach great importance to on-site management blind spots, to find one and eliminate one in time.

Post time: Dec-31-2021